Rescue People Protect the Planet

Rescuing people also means protecting their playground

For over 35 years, ARVA has been protecting people by manufacturing the best mutual assistance avalanche rescue equipment. But in the face of climate change, helping people also means protecting their playground.

Today, everyone has a role to play in limiting environmental imbalance. Greenhouse gas emissions are largely responsible for this imbalance, which is why ARVA launched a sustainability programme in 2020 to establish a clear picture of the brand’s environmental footprint so that we can act effectively to protect the natural environment that fuels our passion for the outdoors.

Measure Reduce Offset

Measure

The first step is to take stock, undertake a carbon assessment and understand our footprint. Faced with this situation, the brand must define objectives for reducing its CO2 emissions effectively. Finally, offsetting helps absorb CO2 emissions by implementing solutions that "sequester" greenhouse gas emissions.

Carbon balance

To determine its greenhouse gas emissions, ARVA has taken into account the processes involved in the life cycle of its products, from the raw material to the end of the product’s life. And what is more, it has also the processes involved in the sale of the products.

Raw materials needed for electronic products or other technical equipment (electronics, aluminium, plastic, etc.)

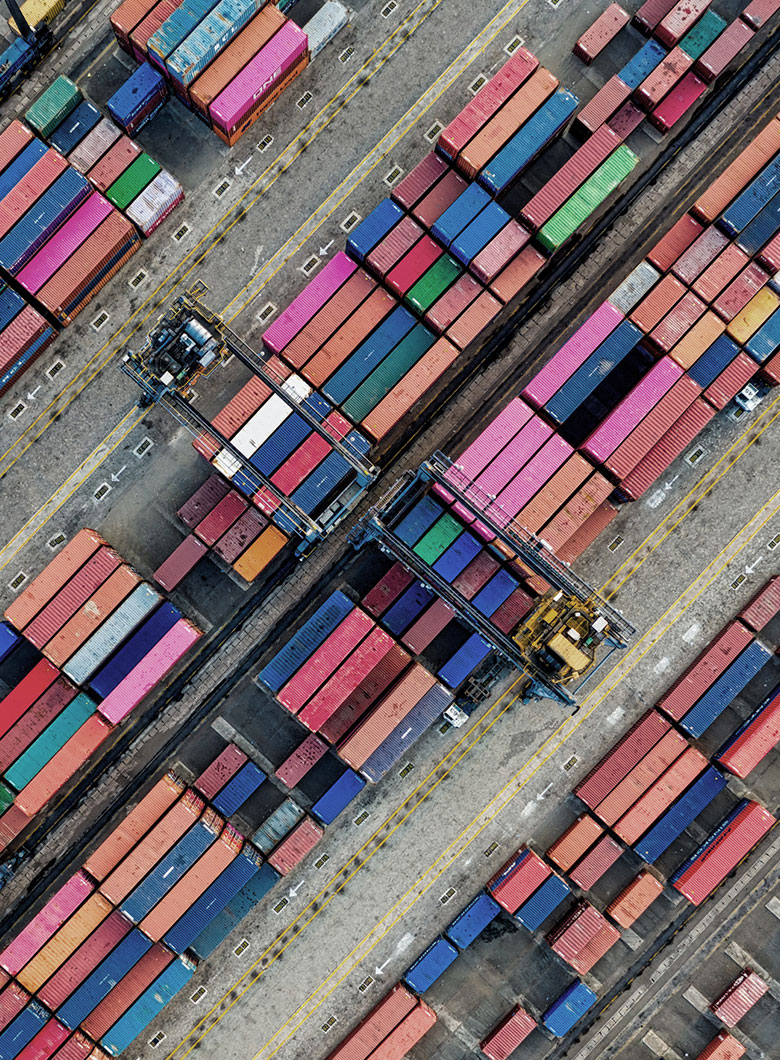

Transport of raw materials to manufacturing/assembly sites (road, sea and air)

Electricity consumption

Packing for transport

Production-related waste

Upstream distribution : Factories > Storage Storage > Stores

Downstream distribution : Storage > Customer (e-commerce)

Electricity consumption of products (batteries, etc.)

Final product (raw materials and initial packaging)

Packaging for delivery

Warehouse electricity consumtpion

Fixed assets (property, computers...)

Home to work travel

Supplier expenses

Office water and electricity consumption

Business trips

Office waste

Advertising / Digital marketing and digital usage

Carbon footprint in 2023

Emissions are calculated according to the GHG protocol, which takes into account six greenhouse gases (CO2, N2O, CH4, HFCs, PFCs, SF6) and expresses the emissions in CO2 equivalent.

Breaking down emissions

Product production and raw materials represent more than 60% of CO2 emissions.

- Raw materials

- 53%

- Headquarters and offices

- 21%

- Distribution

- 10%

- Factories

- 7%

- End of life

- 6%

- Product uses

- 2%

- Freight

- 1%

Raw materials

Aluminium is the raw material that emits most with 31% of emissions.

- Aluminium

- 31%

- Yarn (PA, PE, PP, Recycled PE, PET)

- 31%

- Electronics & LCD display

- 18%

- Carbon

- 12%

- Plastic, PC & POM plastic

- 5%

- Other metals

- 2%

- Others

- 1%

Transport

Transportation between warehouses and shops accounts for 47% of ARVA’s transport impact.

Next, there is FREIGHT (transport of raw materials to factories) with 43% of emissions and transport from factories to warehouses with 10% of emissions.

- 47%of transport impact from warehouse to store

- 43%of transport impact is freight (transport of raw materials to factory)

- 10%of transport impact from factory to warehouse

- 52%Airplane

- 43%Road

- 5%Maritime

Sales

The CO2 emissions linked to sales result mainly from employees’ business or daily travel with 70% of emissions.

15% are related to the energy used in offices and 15% for everything else, including advertising, marketing, computing activities, packaging, office waste, and supplier expenses.

- 70%Employee travel

- 15%Energy used in offices

- 15%Marketing, digital, packaging, offices waste and supplier expenses.

Reduce

Following this assessment identifying the activities that emit the most greenhouse gases, ARVA has set itself 14 objectives to reduce greenhouse gas emissions.

Initially, to maximise efficiency, these objectives will focus mainly on product production and raw materials, which represent the largest share of emissions.

Objective

-15 %

Our 14 commitments

2021

2022

2023

2024

2025

2030

Offset

Faced with the challenges of climate change, ARVA has measured the urgency of the situation. Changing industrial processes, sourcing raw materials and implementing a second-life programme takes time.

But as with avalanche rescue, every second counts! This is why, in parallel with an ambitious emissions reduction plan, ARVA has chosen to offset its CO2 emissions from 2021 and is starting on a path towards contributing to global neutrality.

ARVA – Commited to collective carbon neutrality

From November 2021, every kilogramme of CO2 equivalent emitted by the ARVA brand will be offset by funding carbon sequestration projects in partnership with ClimatePartner.

Partnering with ClimatePartner ensures that greenhouse gas sequestration projects are certified to international standards, are audited annually, and contribute to achieving the UN Sustainable Development Goals.